Production of Photopolymer plates

The production of photopolymer bottles is our greatest know-how. For their production, we use the most modern software and technology on the market.

As the only company in the Czech Republic, we offer ESKO CRYSTAL technology in combination with a KONGSBERG cutting plotter, which ranks us among the absolute leaders on the market in the field of production of photopolymer plates for printing packaging, labels and cartons.

FLEX HD - quality with no compromises

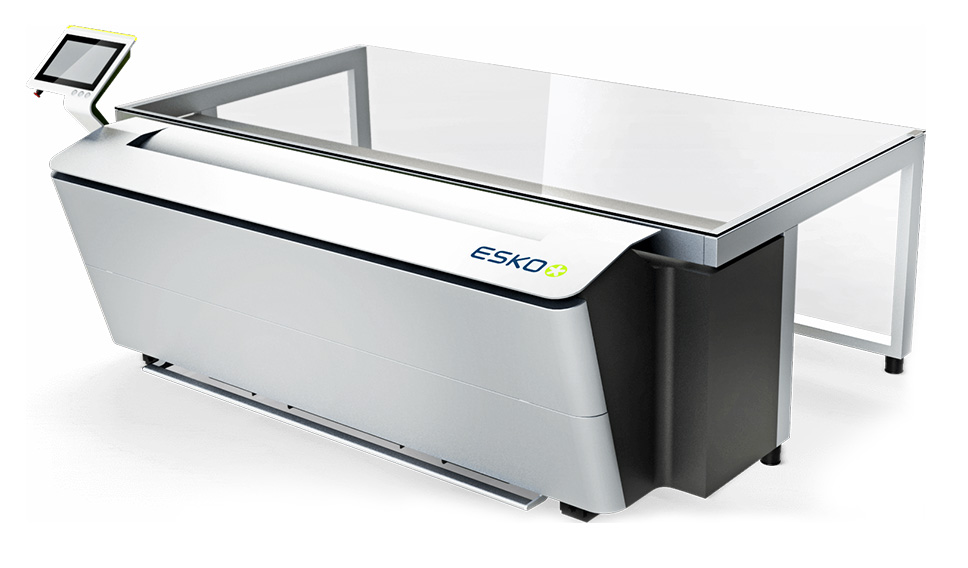

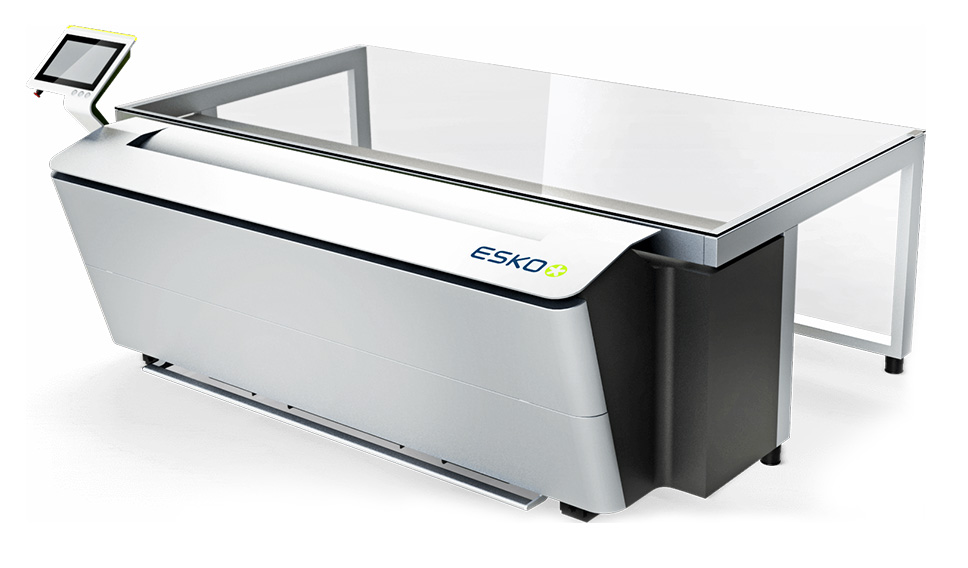

ESKO CRYSTAL – QUALITY WITHOUT COMPROMISES

The ESKO CRYSTAL technology, presented at Drupa 2016, makes it possible to compress the complex process of producing photopolymer rods into a single operation. The key to increasing productivity is connecting the newly introduced XPS CRYSTAL and CDI CRYSTAL devices into one unit.

XPS CRYSTAL:

- XPS CRYSTAL is a new UV LED exposure device from ESKO that combines front and rear UV exposure in a single operation. The combined solution increases the stability of the printing points and thus fundamentally increases the life of the photopolymer plate. At the same time, it reduces the time required for its production.

- In contrast to the old illumination technology, which takes place with the help of UV fluorescent lamps with fluctuating power, the new XPS Crystal equipment uses UV LEDs for illumination, which does not need a warm-up time and always produces consistent radiation, thus ensuring the constant quality of the produced flexographic printing plates.

- Crystal display unit received the prestigious FTA award, 2017 Intertech Technology Award and Red Dot Award : Product Design 2017!

CDI CRYSTAL:

- CDI CRYSTAL, thanks to a powerful fiber laser with high resolution (4000 DPI) and the patented XPS CRYSTAL technology, can produce digital flexographic plates with unique reproducibility and quality.

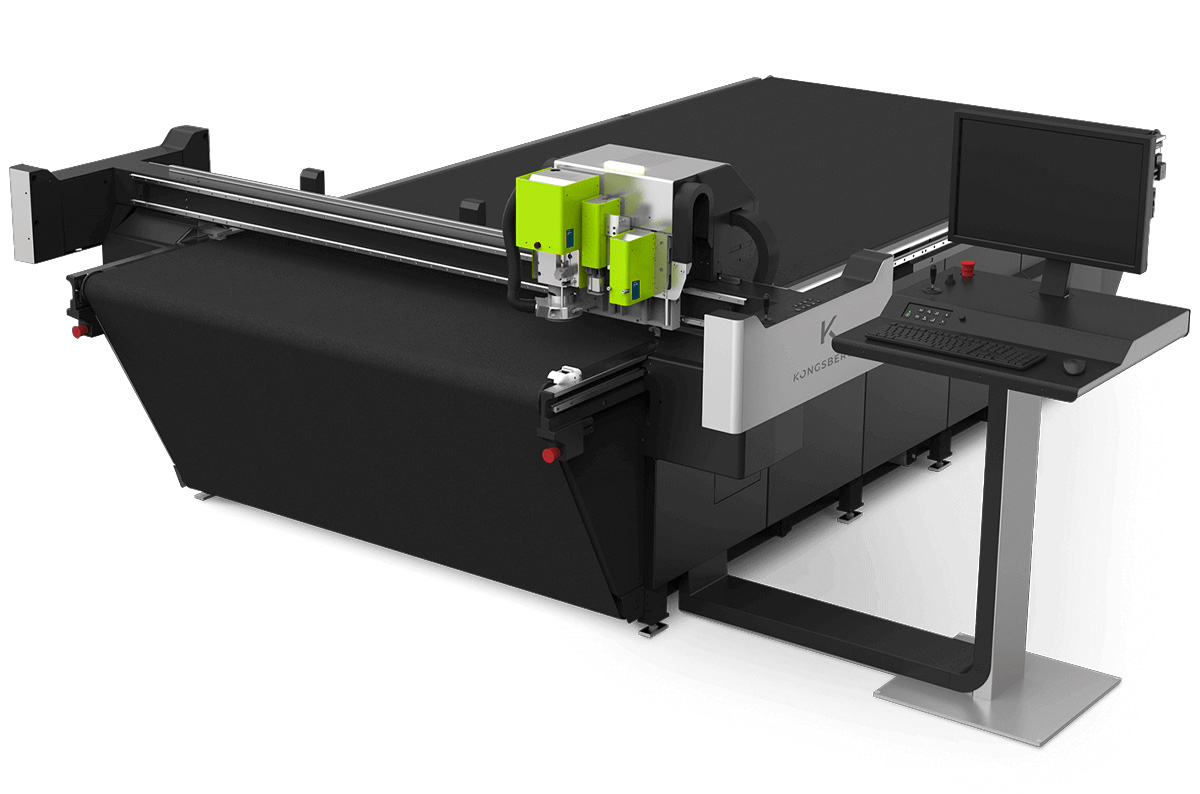

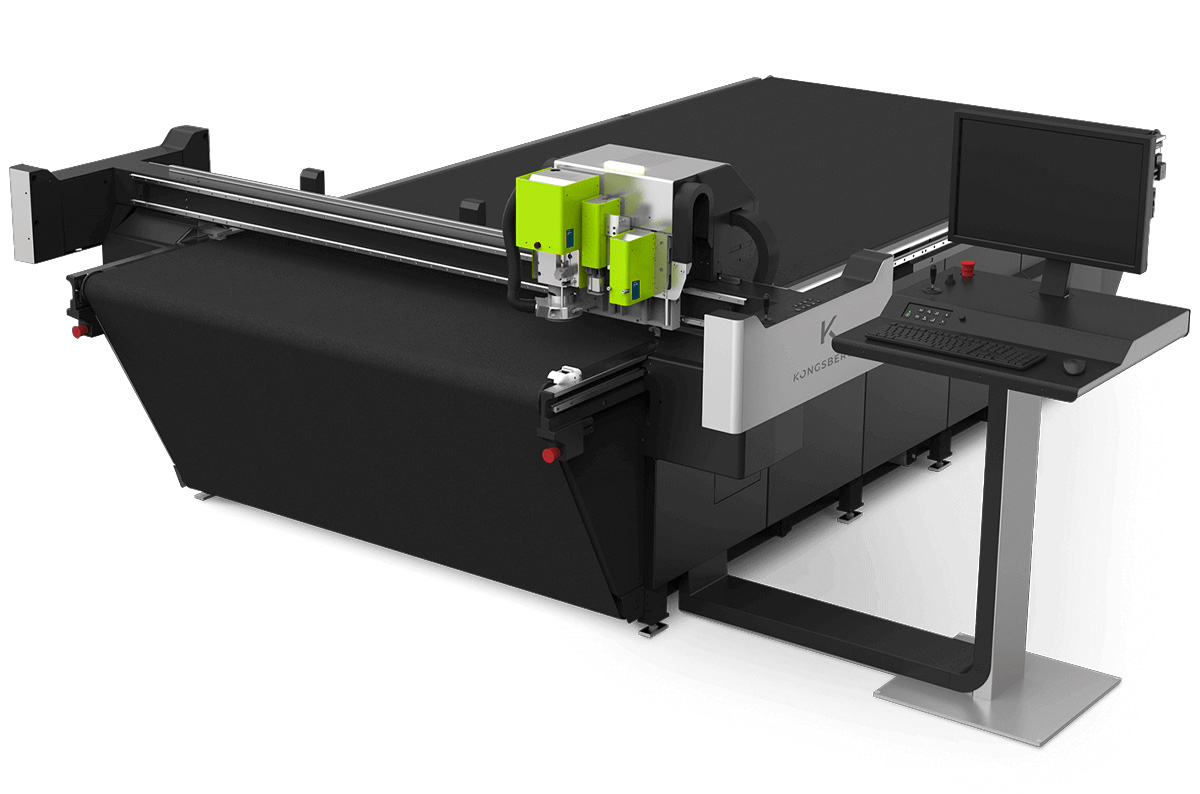

KONGSBERG – TAILOR-MADE DIMENSIONS

The KONGSBERG multifunctional plotter ensures accurate cutting of the photopolymer block. It allows you to accurately cut any complex shape according to the requirements of a specific printing machine.

- A drastic saving of the time needed to install the flexo printing plate in the printing machine.

- There is no risk of damaging the stem when manually trimming it to the required size.